Mine Ventilation

Last Updated on May 10th, 2024

Mining is the most important technique with which we can extract materials from earth. Presently, most mining occurs in open-pits, but with increasing demands on raw materials due to rapid growth in global population and industrialization, underground mining comes to play a critical role in supplying raw materials.

It is well known that underground mining is one of the most dangerous working environments; thus it requires careful design and planning of the mining infrastructure to ensure a safe, productive and relatively comfortable environment. One of the key processes for this purpose in underground mines is ventilation and total air-conditioning, which comprises three distinct parts: quality control, quantity control and temperature humidity control.

To facilitate proper design of a mine ventilation and total air-conditioning system, it is necessary to develop in-depth knowledge of the flow direction to be used, pressure drop as a results of various obstacles, possibility of presence of any kind of fire and explosion, presence of harmful gasses (such as methane in coal mines, radon and diesel emissions) and temperature-humidity profile at various location underneath (depending on the geographical location).

Our works focus on fundamental and applied aspects of mine ventilation and total air-conditioning system as well as introducing innovative ideas for cutting edge research to ensure safe, health and productive mine operation whilst keeping effective and efficient energy consumptions and environmentally friendly mine operations.

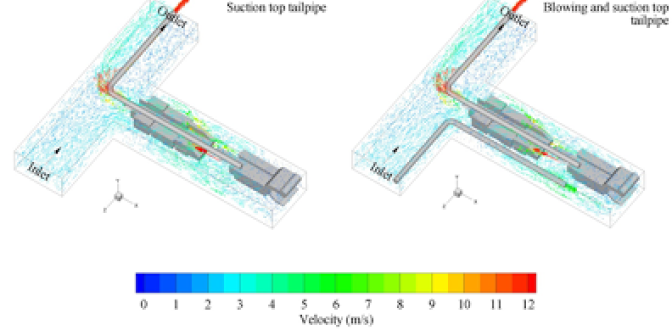

Our group has so far introduced several ways to improve methane controls in underground coal mines, improved design on dust control, diesel emission control and thermal management (heating and cooling) in underground mines.