Artificial Ground Freezing

Last Updated on May 8th, 2024

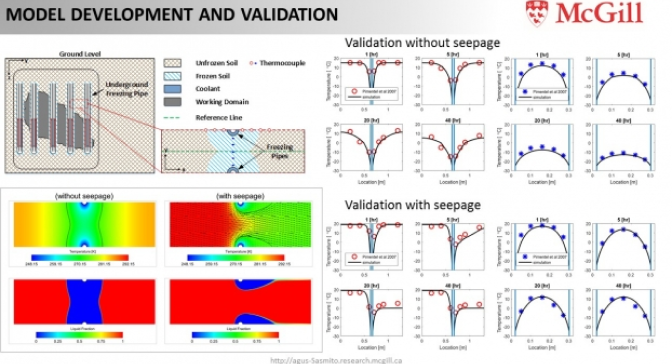

Artificial Ground Freezing (AGF) has been used in civil, mining and tunneling applications to protect groundwater inflow and underground working from contamination and to strengthen the mechanical structure of the ground. The principle of the AGF system is to circulate a sub-freeze coolant fluid in a network of freezing pipes to freeze the ground. As the coolant flows through the pipes, it extracts heat from the soil, and groundwater is, gradually, transformed into ice.

Compared to other geotechnical support methods, such as cement and chemical grouting, AGF has some advantages: compatible with wide range of soil types; lower effect on the ground soil during and after freezing process; low impact on the environment; and more reliable method for high-risk applications, such as uranium mines and hazardous waste management. Despite its advantages, AGF poses very high capital and operating costs as well as intensive energy consumption – and to some extent a large carbon footprint!

The system requires continuous energy supply, ranging from several months/years, such as in Cameco uranium mines, to hundreds of years in the case of sealing-off contaminated areas, such as arsenic contamination in Giant mine and radioactive contamination in Fukushima reactor, in order to maintain the frozen body. Hence, finding an effective and practical method to reduce the energy consumption of the AGF system is of great interest to engineers and specialists in this field.

Our group is working on fundamental and applied research of AGF via experimental and mathematical modeling with the aim to improve and optimize the conventional process. We also introduce novel concepts of a sustainable AGF system in order to reduce capital and operating costs.